Spectrum Powder Coaters Ltd,

High March Industrial Estate (Rear of Vistaplan), Daventry, Northamptonshire,

NN11 4QE

Copyright 2022 ©Spectrum Powder Coaters | Website & SEO by Radikls.

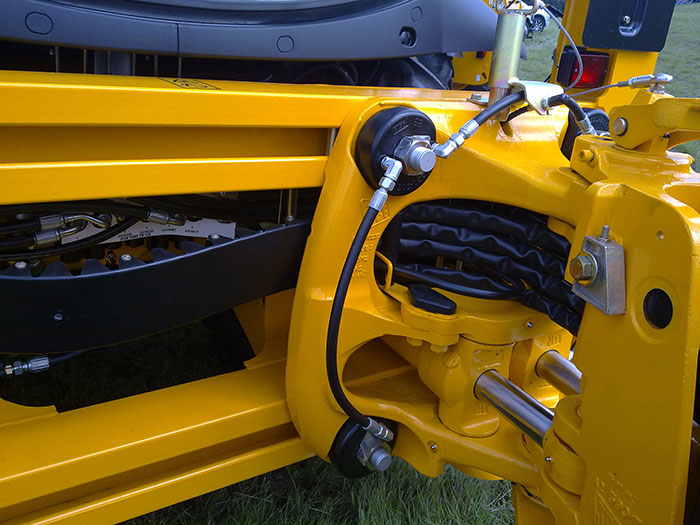

Vixen phoswash parts cleaners to clean and prepare the substrate prior to coating using environmental friendly chemicals. 20 cubic metre Airflow box ovens, all PLC controlled to enable correct dwell time during the critical curing cycle. Reverse jet dry filter powder booths, all waste powder remains in the booth area for disposal. Gema coating equipment.

State of the art on line wash/dry/paint facilty for the coating of large volume quality components

Stage 1: jig & load station

Stage 2: 5 stage phosphate pretreatment

Stage 3: pre treatment drying cycle

Stage 4: Powder coating section

Stage 5: Curing cycle

Stage 6: Unload / pack to customers requirements and specification

Vixen Front Loading

Phoswash

Gema OptiFlex 2 Manual Powder Coating System

Spectrum Powder Coaters is assessed and registered by National Quality Assurance against the provisions of BS EN ISO 9001 : 2015.

BS EN ISO 9001:2015 specifies requirements for a Quality Management Systems (QMS) where an organization: Needs to demonstrate its ability to consistently provide product that meets customer and applicable regulatory requirements aims to enhance customer satisfaction through the effective application of the system. This includes processes for continual improvement of the system and the assurance of conformity and applicable regulatory requirements. Spectrum Powder Coaters has successfully demonstrated that they fulfilled all the requirements in order to be registered against the provisions of: BS EN ISO 9001 : 2015.If you require Powder Coating Services, please contact the specialists at Spectrum Powder Coaters today.

01327 704433